Here's the oil filter canister disassembled and ready for reassembly.

|

The grenade filter is on the engine and this is the oil filter that mounts on the chassis.

|

Andy has gotten the fittings installed and will now mount it to the chassis.

|

This is the oil thermostat valve disassembled.

|

Cleaned, plated, reassembled.

|

Oil filter mounted to the chassis waiting for oil lines.

|

Andy is making current style German oil lines and fittings.

|

We use the current German stuff because it's easier to service and more durable.

|

Oil thermostat mounted in chassis.

|

Andy is making new lines using the crimping tool (this is the floor mounted type, haha).

|

This car has enough parts to make the original type oil lines, the only thing missing is the oil line. This can be purchased (where, we don't know), but we know Warren Eads at Spyder Sports can get it.

|

The oil filler neck and cap have been updated to the factory size.

|

The factory uses a bigger opening because you can get oil in quicker in case of an emergency.

|

Here the tank is ready for installation, including the Perlon carpet that protects it when it's mounted to the frame.

|

Andy has the mock cooler set in to measure oil lines for installation.

|

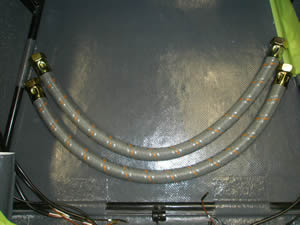

Here are the 2 lines that go from the oil tank and the thermostat to the coolers.

|

Cool.

|

No pun intended.

|

Back to the infamous 906 doors. Bill has earned a King's ransom in the time it's taken to get these things even close.

|

This side will be painted gray after final fit has taken place.

|

White primer, ready for the window.

|

Masked off to protect the paint surface from the epoxy that glues the window to the door frame.

|

Clekos hold the window in place while the glue is drying.

|

After the glue has cured, aluminum pop rivets will be installed in the existing holes.

|