Martini

RSR Conversion

March 23, 2009

We're still trying to catch up to the current build of the Martini car.

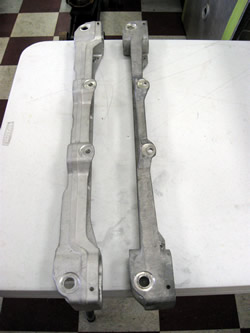

Here's a pile of parts that need to be restored and converted to 5-bolt centers.

Steering rack is bolted up to the original suspension beam.

Now it's all attached & ready to slide in the car.

Tim is setting up the struts and shocks for installation.

The pedal assembly all still worked, but it needs to be re-built.

Note the titanium brake bias hardware.

Here is a racing beam and a street beam.

Delron bushings were used in the day and we're installing new ones.

Note the strengthening gussets on the outside of the torque tube.

All 2.5L and RSR's had this additional metal plate.

Tim uses his iphone of all things, which has a digital protractor,

to set up the torsion bars and the spring plates.

Bingo, ready for installation.

Here's all the bits for the suspension ready to be installed.

Pedal box is now restored and is ready to be installed.

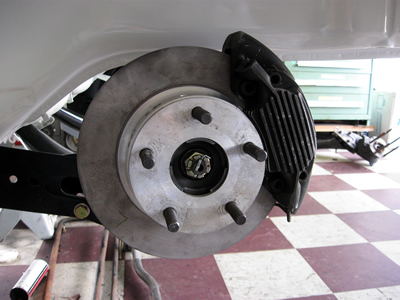

Huge process restoring these original RSR brakes.

You have to replace the broken cooling fins (our little secret)

and the hard anodizing has to be removed from all the cast parts.

The bores are measured before hand so the new hard coat can come out to the same factory specifications.

The brake pucks also have to be restored and hard coated back to factory specs.

The front calipers use titanium hardware, the rear calipers use grade 12 hardware.

New pipes and fittings were used in the rebuild.

These are the brake parts ready for hard coat.

The brake is installed just to make sure that the rotor is the proper dimension

and will be sent out to have copies made.

Andy has got the wiring close to smoke test.

Don't know what close actually means, but in due time.

<<<

Previous Update| Next Update >>>