Crash

Repair 904-006

11/27/01

The car

is still being dismantled and we are starting to make new

pieces.

Here is

the mold for the cross member of the front hood.

The cross

member has just been taken out of the mold.

All of

the excess material has been cut off and the piece is ready

to be added to the hood.

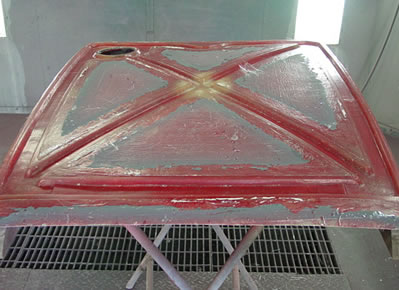

Here is

the mold for the front hood; its gray because it has been

sprayed with DuraTech, which is a polyester primer that acts

as a sandable gel coat. The fiberglass piece will be made

by "laying up" the fiberglass and resin on top of

the mold.

The front

hood is in the process of being layed up. The first layer

is 3/4 ounce mat, second layer 6 ounce german weave cloth,

thrid layer 3/4 ounce mat (for original texture).

Kevin

is completing the layup.

Once all

of the layers of "glass" had been applied in the

mold, the cross member was put on top while the hood was wet.

We then put clamps and as much weight as possible on top to

hold the two pieces together while the resin cures or "goes

off".

<<<

Previous Update | Next Update >>>