906-151

June 20, 2003

The arrow

points to a tube clamp. The tube clamp is tightened around

the aluminum sleeve, then the nut tightens the ferrel into

the sleeve

It sounds easier

than it is because all the tolerances are tighter than loose.

The ferrel is not

tight on the left, but is tight on the right.

Plenty

of anit-seize is used during this process.

Finished product.

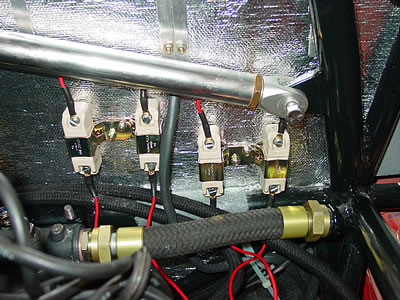

In this

picture, you see the factory resistors and one of the oil

lines completed and installed.

This is part of

the zero tolerance battle.

Here is the before

and after.

The cooler is about

to be mounted.

More signs of new

oil lines.

The car seems pretty

simple until you get it all together.

Oil tank is ready

for installation.

Another view.

Oil tank is in.

Here, one of the

oil lines is installed. The tape in the pictures is to protect

the painted surfaces when installing parts.

We really

lucked out. The cooler was painted gray, when we removed the

paint with paint stripper and the steam cleaner, the original

surface appeared new in looks.

Another view.

We will install

new fittings.

The bracket for

the seat is bolted to the bulkhead.

Both brackets

will receive the seat rails. When the seat slides easily,

the rails will be welded to the bracket.

Because the seat

was lowered (for some tall driver), the seat rails have to

be altered.

The seat works

exactly the same, but the rails sit up about and inch higher

where they slide into the chassis at the firewall.

<<<

Previous Update | Next Update

>>>