904-090

April 21, 2003

Gotta

keep the 904s going! Saturday and sunday I did all the repair

and structure work on 090's original hood.

The hammer

and chisel are the easiest way to get a bad repair removed.

Surprisingly

enough, it was cracked up, but not totaled.

The next

step is to grind all the old glass and resin away.

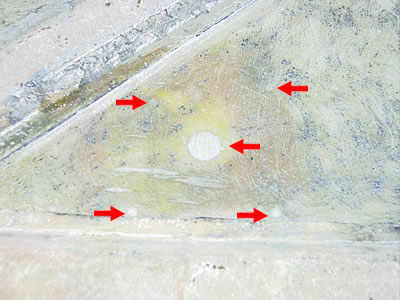

The arrow

points to the front of the hood that I have already re glassed.

The preparation of the front area alone was about four hours,

then I have to grind and repair the rest of the hood.

With the

front being re-strengthened, I can think about repairing all

the other damage from all the crashes a million years ago.

Notice

the body filler. There are two of these areas on the left

and right side.

Here is

a closer look. Because my x-ray vision is not good anymore

I have to grind the area to raw fiberglass and see why these

patches were done.

Bingo!

Looking at the arrows you'll see four 3.5 mm holes and one

13 mm hole in the middle. These holes are from the mounting

hardware of a Cibie hood light.

These

lights were used for night racing, either rally type or closed

circuit. We weren't aware that this car raced at night. This

is good news because we might find out that it did something

better than just hill climbs and club races.

Simple

little holes can be the biggest provider of information. That's

why it's important to take your time while you strip these

race cars.

Another

six hours later, the rest of the hood has been ground flat

in preparation for repairing the cross structure and re skinning

the flats.

Other

than the damage up front, the rest of the hood is in fairly

good condition.

Another

view.

Another

view.

Now I've

made 3/4 oz matt panels to fit perfectly in the openings.

I layed

up each opening using black pigment in the resin (remember

it keeps scratching marks to a minimum). When it cured, I

taped off the finished panels as to not get any filler or

primer on the surface.

I use

five layers of tape so when I apply filler to the structural

panel it leaves a perfect edge where it needs the fiberglass.

This is

tedious work, but it's a way to make the hood very strong,

light, and great looking.

I have

applied filler to the repaired areas and to fill the million

pinholes caused from sandblasting.

I'll duratech the structural "X" in the morning.

<<<

Previous Update | Next Update

>>>