904

Floors

April 4, 2003

To get

proper floors for 904-119 and 904-068, we are going to use

904-090 as the plug.

But first,

we have to restore it.

Which

is good news for everybody!

So this

means picking the pace up on all three restorations.

In all

these pictures you can see areas of hard racing use.

The gray

in the middle is original, the red is over spray from the

second coat.

There

must be 50 areas that need repair.

To repair

the cracks and rivet holes, you have to grind at least half

way through the panel to build it up to original thickness

with new glass.

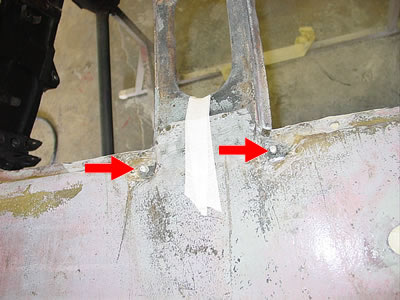

The arrows

point to the original 6 mm studs that attached the floor to

the chassis.

This gives us perfect index marks.

There

isn't an area on the floor that doesn't need repair.

We will

make the mold of the floor next week.

Two more

pounds of crap ground off the bottom.

The floor

has now been repaired and the coating you see is body filler,

filling in the million pinholes from grinding.

All three

904s are in this picture.

I don't

think anybody has a proper floor mold, that would actually

make parts for customers.

All the

areas in the next pictures need attention, so the mold makes

original looking parts.

Another

detailed picture of an area that needs to be saved.

This floor

panel has been knocked loose from various crashes. I will

remove it, restore it, and make a mold of it because we need

this mold to finish our 904 projects.

Here is

one of the jack spur holes restored to the original shape.

The panel

has now been removed. The metal of the chassis in this area

is in perfect rust-free condition.

This panel

is actually one piece, but had to be cut out in two pieces.

I'm holding

one of the glass straps that had popped loose.

You can

see the cut. The panel will go back in whole because the glass

in the area will be removed before reassembly.

When the

floors are complete we will start gluing the bodies on the

other two cars.

<<<

Previous Update | Next Update

>>>