904

Floors

April 7, 2003

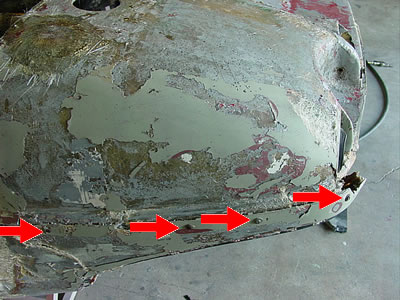

Because

of hard racing use and a few good crashes, there are cracks

everywhere that need to be repaired.

The arrows

point to sheet metal screws because the last time the car

was raced it crashed. The mechanic just screwed the fender

to the lower nose piece.

Still

don't know what this hole was, but we filled it up. The other

hole is for the horn.

This brake

scoop is actually PVC plastic. It succumbed to a crash and

had a fiberglass matt dressing poured on it....some fix!

The areas

that appear to be wet, were ground to bare glass and repaired

with matt.

This is

the front left fender that was screwed on. We'll glue the

fender back on after it's repaired and the car is turned back

upright.

Pretty

ugly, but we do know what the original shape is.

More patching

going on. You can see the front has been completely ground

to bare fiberglass.

The front

leading edge also needed repair. Note: the stick, this holds

the nose up in place while the repairs are going on.

Fiberglass

is a great material, but boy does it break when it's hit.

Back to

original shape.

The black

is actually paint from the inside, then covered with matt.

I ground it down right to the paint from the outside, thus

getting rid of all the fatigued glass. It's been covered with

two layers of 1 1/2 oz matt.

All the

repairs are done and sanded to a nice finish.

The next

step will be filling in the imperfections.

This is

where bondo becomes my buddy!

These

brake ducts will be remade after the bottom is painted with

duratech.

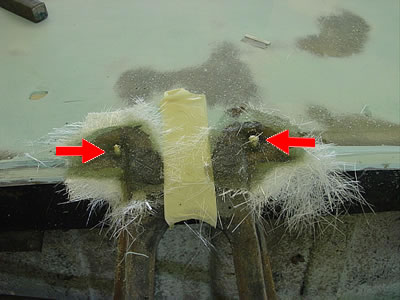

These

are the two index bolts which also hold the back of the underbody

to the chassis. These were in need of major repair.

Sweet!!

Ready for duratech.

<<<

Previous Update | Next

Update >>>