906-127

May 5, 2006

I finally

made the molds for the carburetor tops (glass fiber). These

seal the hot engine compartment to the top of the rear deck

lid so the carbs can get fresh cool air rather than sucking

in the heat from under the deck lid.

Andy is

doing the final sand and prep for the final paint.

I normally

paint all the fiberglass two times. This gives it a good base

and it lets the paint shrink into the imperfections on the

surface of the gel coat before applying the second coat.

I re-primed

where Andy has filled with polyester surfacing puddy.

This will

be sanded and painted on Saturday. Next week, we will put

the finishing touches on 127.

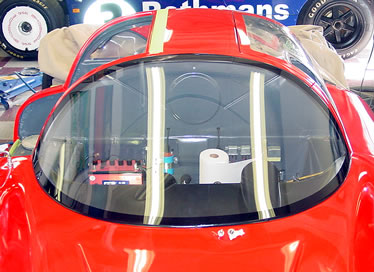

Andy is

putting the last fit on the windscreen.

I've used

urethane satin black to paint one inch on the edge of the

inside of the windscreen. This enables the window man, Harry,

to spread the black urethane cocking at least up to an inch

wide, which makes for better adhesion and the look on the

outside of the window is a neat and clean blacked out edge.

Harry

tapes the edges,which eliminates a mess, then uses his Milwaukee

electric cocking gun...man is that thing cool. No more bumpy

cocking lines. Do I feel weird saying cock so many times is

one paragraph?!!

Oh yea, this is the cockpit windscreen. Should we call him

"Harry the Cocker"?

After

he's done with the urethane, he uses a special suction cup

grab handle and places the windscreen on a determined mark.

With a

little pressure, the urethane relaxes in an even thickness

all the way around the window.

Now he

peels the protective tape from the inside, because if the

urethane cured on the tape, you wouldn't be able to pull it

off. So this is done when it's all still wet, leaving a perfect

edge.

This sits

for 24 hours, then Andy peels the protective paper from both

surfaces, cleans the window, and waits for Harry to come back

and fill the outside edge with black urethane. (The owner

made the choice to use glass instead of plastic and then changed

his mind because plastic is lighter, safer and stronger.)

The next

day, the base urethane is dry and the window is actually attached.

Now, Harry fills in the outside groove.

Harry

dons a glove and fills the groove with the same black urethane.

He uses his finger to leave a perfect surface on the sealed

edge. Believe it or not...he licks his finger to moisten the

end, which keeps his rubber glove from dragging the urethane

to an ugly finish. If you don't wet your finger, the urethane

does not smooth out.

This is

tedious, but the finished result is beautiful.

Harry

now pulls the tape off thus leaving a perfect seam around

the windscreen.

Wow...doesn't

that look great!!

And now for a bonus...a few more historic

photos

1966 Berchtesgaden

Historic Photos Courtesy

of Sepp Greger - Reproduction Strictly Prohibited

<<<

Previous Update | Next Update

>>